R&D Area

We introduce the beginning of automobile component technology of Hwashin.

- R&D CENTER

- R&D AREA

At the automobile development stage, a virtual model is designed on computer and CAE is conducted under various conditions. Verifying the performance of components before manufacturing a prototype, we enable optimized product design and production and contribute to a reduction in development costs by shortening the development period.

-

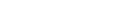

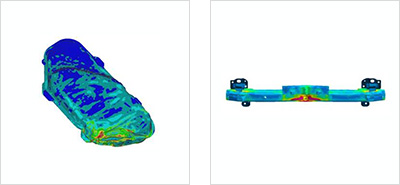

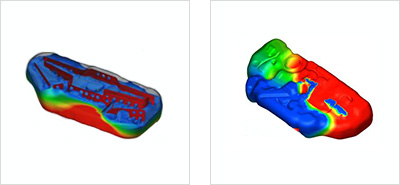

- Prediction of the service life (fatigue & durability) of components of an automobile under repeated load.

- Suggestion of durability improvement

-

- Verification of the compliance of bumper rails with the automobile safety regulations.

- Verification of airtightness of a fuel tank in a collision

-

- Verification of buckling strength and rigidity of pedals

- Verification of buckling strength of arms and links

-

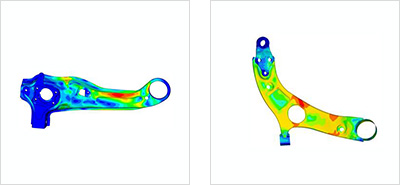

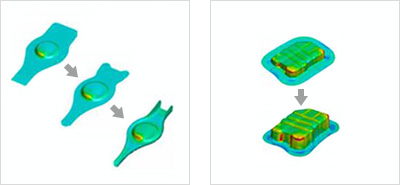

- Characteristic optimization through CAE of kinetic features of a virtual automobile for improving the control safety and riding comfort.

- Calculation of dynamic stress and durability load conditions of each component through reproduction of a durability test

- Calculation of static characteristics

-

- Prediction of noise due to movement of fuel in a fuel in a fuel tank from braking

-

- Prediction of problems due to tear or wrinkle occurrence by calculating thinckness and deformation during forming.