TECHNOLOGY CENTER

We introduce the beginning of automobile component technology of Hwashin.

- R&D CENTER

- TECHNOLOGY CENTER

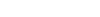

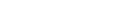

PLM SYSTEM

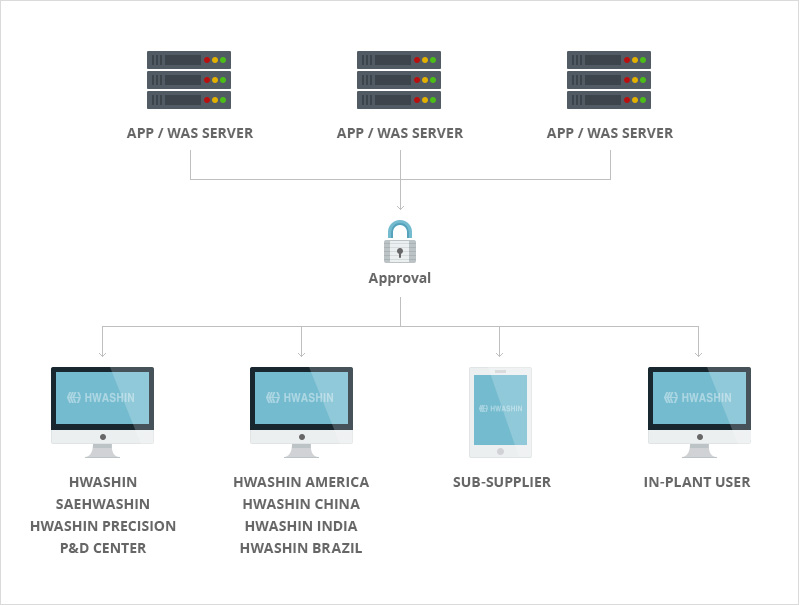

The PLM System, standing for product life-cycle management, refers to a system that comprehensively manages information related to the product life cycle encompassing from production to disposal. Hwashin established the enterprise computational management system ‘eMatrix PLM System’, in order to jump up to be a global automobile component manufacturer by managing simultaneous development works performed by its domestic affiliates and overseas corporations with concurrent engineering computational environment.

With the construction of the PLM System, the following results are expected.

Firstly, the work relations can be standardized and the improvement work procedures can be systematized by comprehensively managing all components information, BOMs, design modifications, documents, and drawings generated from product development. Secondly, it is possible to standardize design BOMs, to systemize works related to ECO management and the enterprise resource planning (ERP) system, and to manage work process through workflow. Thirdly, the system that comprehensively manages projects can be realized and the management process can be simplified through work standardization. Fourthly, it can result in development cost reduction, improvement of design quality, and development lead-time reduction by improving the recyclability of technical documents, materials, and data.

ERP & PLM Link